Thermowood – the best solution for manufacturing saunas

Thermal wood is one of the best materials for the manufacturing of saunas and hot tubs, as well as for construction, decoration, interior design, and rooms with high humidity. This is due to the excellent performance and decorative properties.

To make it long lasting, the materials used in the manufacturing of saunas and wooden hot tubs must have high moisture resistance and be less prone to decay. That is why the best option is heat-treated wood.

Remember that thermally modified wood is still natural wood and possesses the same properties as natural wood. It expands, contracts, or dries out depending on humidity and temperature, and may crack just like regular wood, but these processes occur much less frequently than with untreated wood. Our thermally modified wood is wood that “moves” approximately 60% less than, for example, plain spruce.

However, 60% is not 100%, which means that thermally modified wood still moves significantly, requires regular maintenance, and should be painted or glazed after assembly/receipt.

Thermowood Production Technology

To produce Thermowood you should treat the ordinary woods in an airless environment with high temperatures. Manufacturing technology of thermowood differs from conventional woodworking. It is a thermal treatment of wood at 185-205°C so that the material acquires unique properties and becomes almost eternal. Unlike usual, the sauna from the heat-treated wood does not absorb moisture and does not rot, does not crack. And over time, there are no cracks between the boards. This wood is geometrically stable, has a pronounced texture, and has antiseptic properties.

The thing is that during the processing the cellular structure of the wood changes. It becomes as dry as if it has been drying for several hundred years. Resin completely evaporates from wood, and it acquires a deep, dark color, its thermal conductivity decreases, strength increases, and water absorption significantly decreases (by 3–5 times as compared to ordinary wood).Besides, the material is weakened dramatically and strained. As a result, thermowood saunas remain more stable with the changing temperature and humidity and retain their geometry.

Thermowood – the best solution for manufacturing saunas

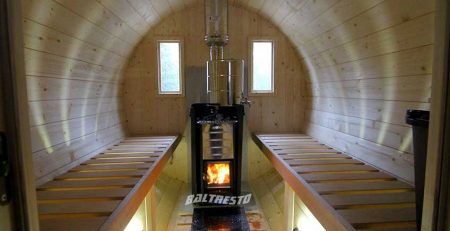

Wood and the elements that make up the sauna determine its durability and comfort of use. The shelves made of ordinary wood heat up much harshly than thermowood. Sometimes, sitting and lying on them feels uncomfortable even after covering it with a sheet or towel. Unlike conventional wood, thermowood heats up much less. Even when the heat set to the max limit, this material has a comfortable temperature for human, eliminates the risk of burning, and, therefore, increases the safety of staying in the steam room.

Sauna Interior Design: unlimited possibilities of thermowood

The color and texture of the thermowood depend on the type of wood and the processing temperature. Wood of any species that is heat-treated can have at least 2 shades and 2 types of texture. It offers unlimited possibilities for your fantasy in the interior design of the sauna.

In general, alternating bars of different colors can achieve an unprecedented effect. Moreover, heat-treated wood, unlike conventional wood, does not change color and texture during operation in conditions like high temperature and humidity.

Sitting on the shelves of absolutely smooth heat-treated wood feels so nice. Also, with a clear drawing of the texture, as well as uniform, vibrant shades, this material can serve as a real decoration of the interior.

The Advantages of Using a Thermowood Sauna

- Eco-friendly and does not emit harmful substances into the atmosphere.

- A high wear resistance and durability.

- It is more resistant to rot or mold than untreated wood

- Thermowood Sauna will be less deformed due to extremes temperature and under the influence of moisture than a sauna made of spruce

- It has high thermal insulation properties.

- Various colors and shades.

- Safe to use.

The disadvantage is the high cost (compared to the conventional wood) due to the technological difficulties faced in the production of thermowood.